Ceramics are fired according to a cone schedule. Thinking of the range of cone temperatures like a thermometer can help alleviate confusion.

Different clay bodies and glazes mature or vitrify at different temperatures. What temperature to fire a particular clay is described by a cone. Ceramic cone temperatures range from 022 to 42, although clays used by ceramic artists will fire between cones 06-10.

Ceramic Cones as a Thermometer

Think of ceramic cones as a thermometer. The temperature between cone 06 and cone 6 is approximately 400 degrees, just as 40 degrees Fahrenheit and -40 degrees Fahrenheit are not the same number and are separated by 80 degrees of temperature.

There is no cone zero, so think of cone 1 as the zero point. All the cones below cone 1 are preceded by a zero. These are equivalent to negative numbers. For example, cone 01, cone 02, cone 022 represent a lower temperature than cone 1. As with negative numbers, cone 01 represents a higher temperature than cone 02.

Common Firing Temperatures and Cones

Here are some of the more common cone values and approximate firing temperatures:

- Low fire ceramics – 1828 degrees Fahrenheit – cone 06

- Stoneware ceramics – 2167 degrees Fahrenheit – cone 5

- Porcelain ceramics – 2345 degrees Fahrenheit – cone 10

- fused glass – 1485 – cone 014

- china paints – 1252 – cone 018

Use of Pyrometric Cones

Pyrometric cones are used to gauge the temperature of a kiln and the temperature of the clay within the kiln. Pyrometric cones are cone shaped objects placed in the kiln to determine the temperature of the kiln and how much heat the clay has absorbed. Cones are available from cone 022 to cone 10.

A kiln with a kiln sitter will need a small cone placed in the kiln sitter device. When the kiln reaches the desired temperature, the cone in the sitter will bend. The bent cone mechanically shuts off the kiln.

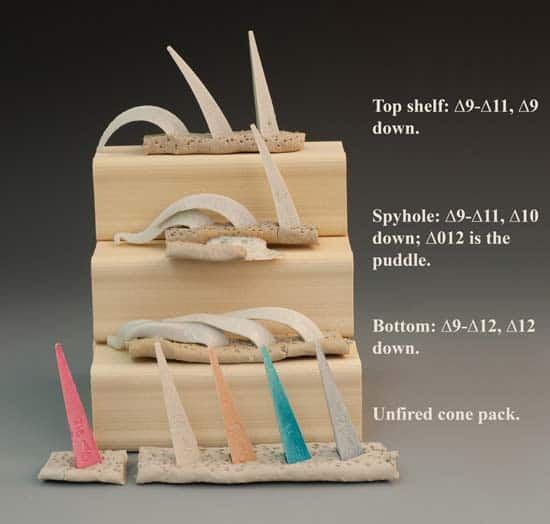

Larger, self-supporting cones are placed on a shelf, usually in sets of three. One cone, called the firing cone, is the temperature desired. The guide cone is one number cooler and the guard cone is one number hotter. At the desired temperature and heat absorbtion, the guide cone will be bent completely over, the firing cone will be bent at about 90 degrees, and the guard cone will not be bent.

Using this system, a potter can determine if a particular firing did indeed reach the desired temperature and heat absorbtion. This can be critical for glaze maturation and glazes that are food safe if fired to a particular cone. Cones can be placed on various shelves to determine differences in temperature within the kiln.

Ceramic cones can also be used in gas and wood kilns which have no apparatus to shut the kiln off automatically. In this case, the potter will place the cones in view of a peep hole which the potter will check periodically.