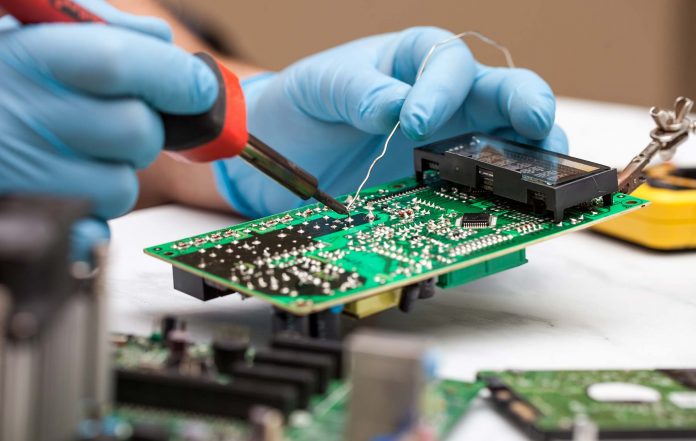

Introduction to basic soldering techniques. Know the types of soldering method used in the industry today. and know the basic soldering iron tip care guide.

Soldering is a process of joining 2 pieces of metal with solder, without melting of the base metal. the joint gap is filled with a molten alloy (a mixture of 2 or more metals, e.g. tin, lead, silver), which has a lower melting point than the joint members themselves, but which is capable of wetting them and solidifying to form a firm and permanent bond between them.

Three types of soldering methods

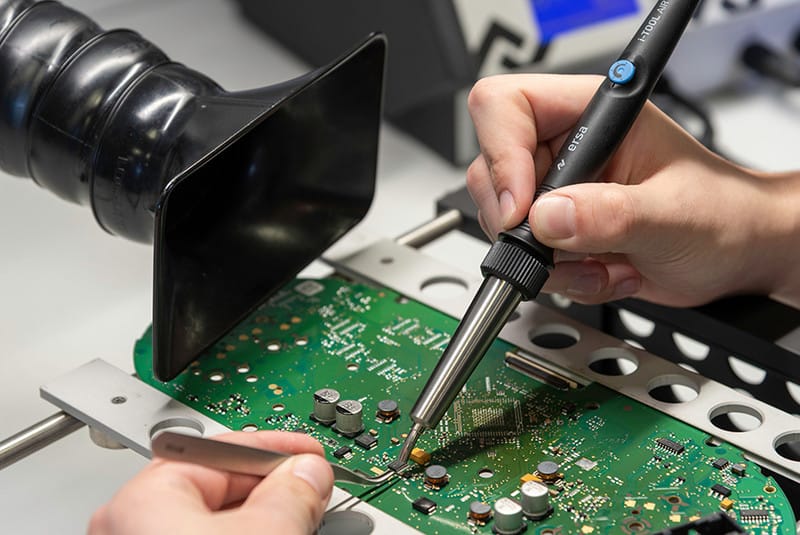

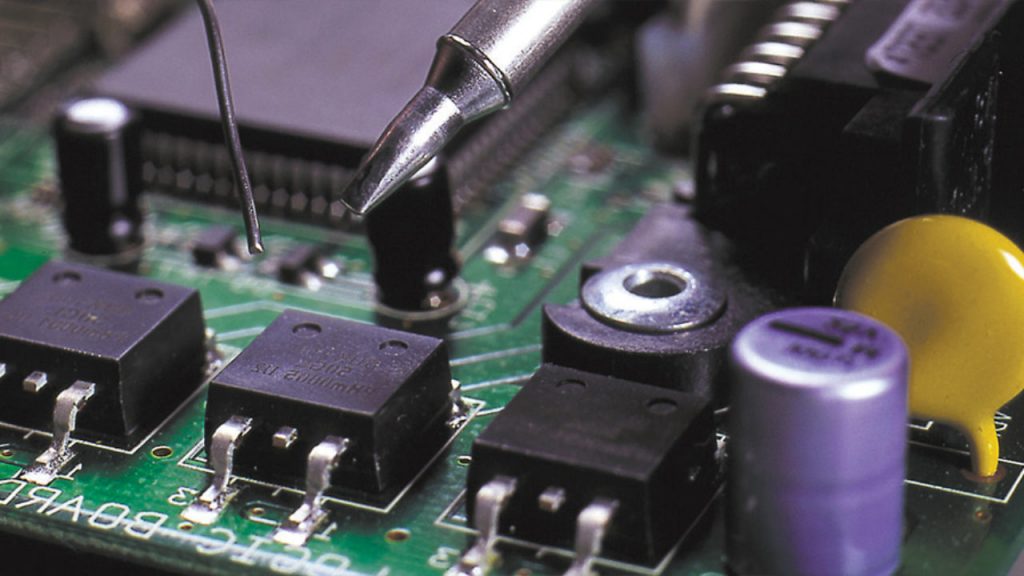

- Hand soldering – commonly use for soldering two pieces of metal using soldering iron, solder wire with flux. In an electronics industry, the temperature of the soldering iron is controlled in order not to damage the components being soldered. This is because advance component packaging for resistors, capacitors, IC’s diode, etc are very sensitive to heat stresses and are easily damage if heating is not controlled. Normally, the maximum temperature of the soldering iron is keep at around 320 +/- 10°C.

- Wave soldering – an old technology use to solder pin-through hole (PTH) components using a wave soldering machine. Molten solder is melt in a solder bath and is pump by a motor creating a solder solder wave. The temperature of the solder bath is kept at 250°C maximum. As the PTH component mounted on the Printed Circuit board (PCB) passes through the wave, the solder in contact with the PTH pins and PCB pads is soldered.

- Reflow soldering – use to solder surface mounted devices (SMD) using reflow oven machines. Uses solder paste.

Soldering iron tip care guide.

In order to prolong the life span of your soldering iron tip, here’s some guide to keep your tip working.

- Select the right tip for the job. Do not use extra large tip to small components.

- Use minimum pressure when soldering.

- Keep your sponge clean and moist.

- Re-tin after use before storing. Adding solder on the tip to coat it and prevent oxidation build-up.

- Turn-off the soldering iron when not in use.

Always wear protective equipment (glove, face mask, goggles, etc.) when doing any kind of soldering to protect from harmful elements such as lead, heat and flux fumes. Following the procedures in the right sequence the first time could mean working through a simple yet reliable soldering. The best way to make an electronic connection not to work is to make a poor soldering. And the only way to be sure of a good solder joints is to “DO IT RIGHT THE FIRST TIME!!!”.